“World hunger is not a supply problem. It’s a logistics problem”, these are the words Tilak Dissanayake opens our conversation with. According to the World Food Programme, approximately 795 million people today do not have enough food to lead a healthy active life. That’s one in nine people on the planet going hungry. Inside a two-story house in the middle of Havelock Town, Tilak and his team have a solution to the problem: drones.

In recent times, we’ve seen drones of all shapes and sizes over our skies. Sri Lanka is no stranger to building them either, just ask the folks at the University of Moratuwa who have built surveillance drones. Tilak and his team’s mission is very different in that they intend to build a massive air cargo network, complete with airports and airlines that use low-cost, rugged drones to solve world hunger.

Say hello to the Robotic Air Cargo Network

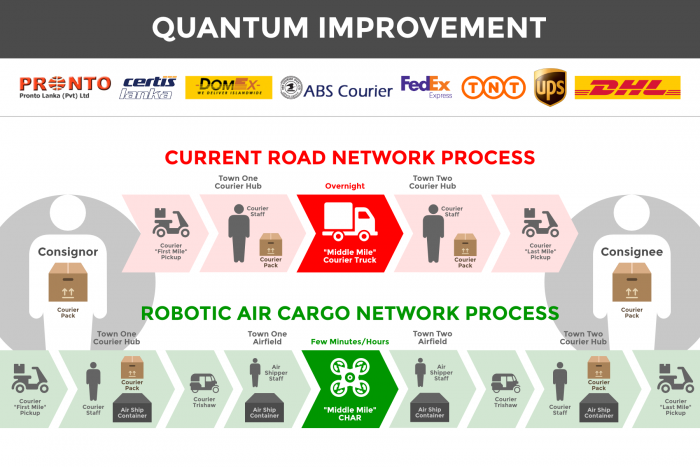

Solving world hunger involves getting the suppliers and consumers of food connected in the most efficient way. Since there are myriad factors such as selling, buying, and payment in addition to the air logistics aspect of delivery, Tilak and his team are focusing initially on proving the concept of creating a Robotic Air Cargo Network (RACN) for courier package transport. The initial RACN, which Tilak and his team envision is one that can be used for middle mile transport. To best understand this network, one needs to first look at how couriers transport goods today.

Imagine you need to have a package shipped from Colombo to Kandy. You call a local courier such as Pronto, Certis Lanka, Domex or Abans and they come and pick up your package and transport it to their hub in Colombo. This is the “first-mile” stage.Your package is then shipped overnight via truck to the courier hub in Kandy. This is the “middle-mile” stage between hubs. From the Kandy hub, your package would be delivered to the recipient. This is the “last-mile” stage.

What the RACN initially focuses on revolutionizing is the middle-mile stage. After the “first-mile” pick-up, the courier would put the package into a standardized shipping container designed to fit into the drone, and send the container to the drone airport in Colombo. The airline would load the container into a drone, which would then fly to a drone airport in Kandy in less than an hour. The courier picks up the container at the Kandy airport and takes it to their Courier hub in Kandy, from where the “last-mile” delivery is done. Overnight delivery reduces dramatically with Colombo to Nuwara Eliya in 90 minutes, and Colombo to Jaffna in mere 4 hours.

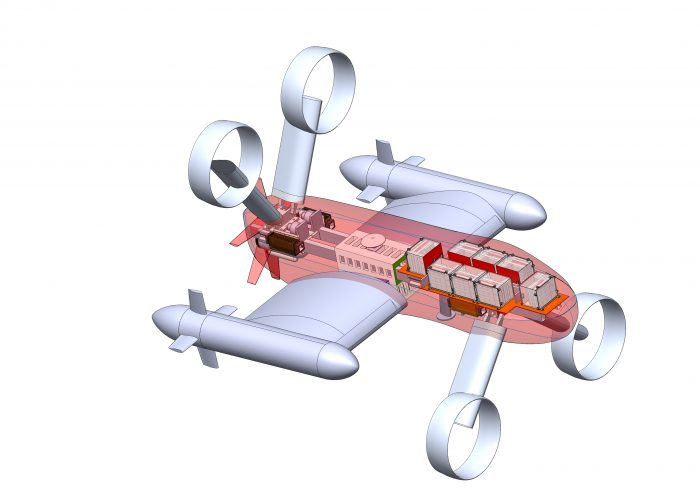

The Robotic Air Cargo Network consists of five components. The first of these components is the Courier Hub Air Robots (CHAR): The fully autonomous, Vertical Take-Off and Landing (VTOL) all-electric drones that carry up to 20kgs of cargo. The 300kg, 2.5m wingspan CHARs will cruise at 200kmph. The CHAR will be certified to the JARUS (Joint Authorities for Rulemaking on Unmanned Systems) certification standards. The battery pack provides a range of about 60km and can be swapped in less than 10 minutes at refuel stations along the way. The CHAR has a parachute that lowers it safely to ground in the unlikely event of a system failure or a bird strike to minimize harm to people or property on the ground.

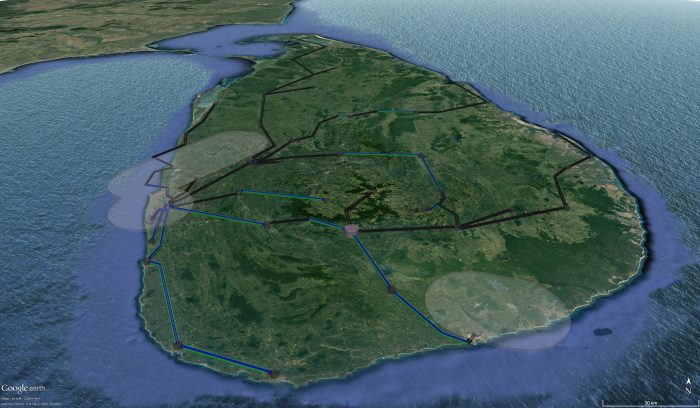

The second of these components is the airports that will be specially designed for the CHARs. The VTOL CHAR only requires a 5m diameter pad to operate from. A modular terminal with cargo handling, hangers, and pads would require only a few hundred meters by a few hundred meters, and can easily be located in a large paddy field close to town. Each of these terminals can handle over a hundred landings per hour, so tens of thousands of kilograms of cargo can be moved in a day.

The third component of the RACN is the airways. The CHARs fly in 300m wide by 200m tall airways between airports. The inbound and outbound lanes are separated horizontally by 500m, and additional tiers can be added as traffic increases. The airways are segregated from other air traffic and are 300m plus above the highest point between airfields per International Civil Aviation Organization (ICAO) regulations. The CHARS fly nose-to-tail in the airways separated by 2 km between them at 35-second intervals.

The fourth component of the RACN is the Air Robot Traffic Management System (ARTMS). This is a collection of systems that coordinates the CHAR from take-off to landing and provides separation assurance to make sure no mid-air collisions happen. Human Air Traffic Controllers (ATC) play a supervisory role in case the multiple-redundant systems on the CHAR or ARTMS fail.

The fifth and final component of the RACN is the Robot Cargo Airlines. The CHARs are owned and operated by an airline that has no pilots. The CHARs have been designed to be “smart” so they will refuse to fly if not properly maintained. The shipping container is also smart so that the airline can never ship it to the wrong destination. The CHARs also are very easy to maintain with most of the units replaceable on the flight line to maximize operational uptime.

The challenges of building the RACN

When it comes to designing every aspect of the RACN, Tilak adopts the approach of the infamous AK-47 assault rifle. The AK-47 with its low-cost design, simple construction, durability, and ease of use creates a powerful recipe for success to function reliably. It is one of the greatest examples of modern industrial design with an estimated 100 million manufactured worldwide.

Achieving such simplicity can be a tough challenge. Nonetheless, for Tilak and his team, this level of simplicity is essential. Tilak and the team ensure that the entire RACN complies with myriad regulatory standards. Balancing conflicting goals in product design can be a tough challenge. Tilak and his team will design, concept demonstrates, and “certify” all five components of the RACN. The CHAR will receive a type certificate (think of this as an “international patent”) from the Civil Aviation Authority of Sri Lanka (CAASL) and will license it to manufacturers and earn money through royalties.

For the ARTMS application software and the CHAR avionics embedded software, it is required that the system designers use the waterfall method to ensure that a piece of code can be traced back to a regulatory or functional requirement. To anyone in the commercial IT industry, this would sound absolutely insane. It would mean developing a system using a method that is considered outmoded by the local IT industry and Tilak accepts the fact that he will have to train his software engineering team in a development approach that is quite alien to them.

Once operational in Sri Lanka, the entire RACN can be exported to other countries since it is certified to international standards. The RACN represents an enormous economic export opportunity for Sri Lanka. At US$20k per CHAR, and conservative worldwide market potential of 2-4 million units, the exports would be approximately US$40-80B in comparison to our current total exports of US$30B. This does not include the revenues from battery packs and transaction fees from ARTMS usage.

The origin story of Tilak and his drones

When it comes to designing aircraft, Tilak brings a wealth of experience to the table. After finishing his schooling at Royal College, he attended the University of Hawaii where he obtained degrees in Mechanical Engineering. Tilak joined the Boeing 767 program in Seattle in 1978 and worked in the propulsion systems group. After 767 certification, he moved to the defense side and worked on many classified programs in an Operations Analysis group. After 12 years at Boeing, Tilak moved to Xerox where he worked for 7 years. Tilak then moved to Silicon Valley at the start of the Internet boom in 1997 and worked at various startup companies including Netscape.

After 30 years in the US, Tilak returned to Sri Lanka in 2001, and first entered the world of entrepreneurship building a patented dog tag cover. Once that project ended with a nuisance lawsuit, he returned to the IT industry to work at the Bartleet Group in 2007. There he invented, concept demonstrated and filed a patent for an SMS-based payment system called ROKA. He resigned from Bartleet in 2009, and started a new firm called Ants Global.

Tilak and his team designed and built a van sales system on a Windows Mobile smartphone with full inventory management and real-time sales reporting. After three years of development (including a pilot field test with Atlas), Microsoft redid its mobile O/S rendering its code obsolete. Soon after they started an Android conversion, the young lead programmer died of a heart attack, and Tilak halted the project in mid-2012.

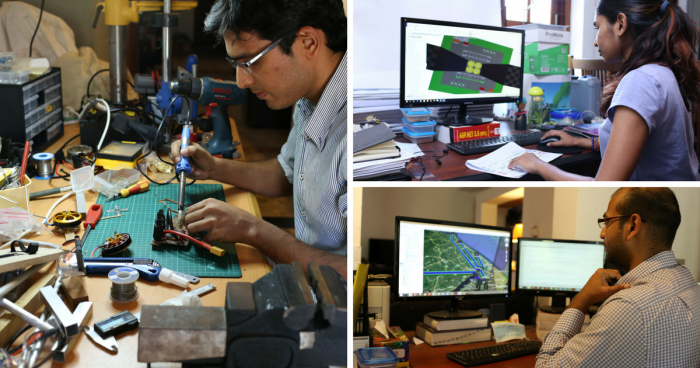

Tilak was undaunted by his failures and considers them valuable lessons learned, and began in 2013 to work full-time on the RACN using his pension from Xerox and Boeing. Tilak teamed up with Arjuna Mendis (electronics engineer) and built the Mark I prototype CHAR to demonstrate that a non-planar quadcopter with a wing and no control surfaces would be an effective aircraft for courier package transport. Their pitch control concept demonstrator worked and now it was onto the next stage.

Tilak and Arjuna began working on designing the real CHAR drone and the other components of the RACN such as a 15 Kw Switched Reluctance Motor (SRM) and a motor controller to run it. For a brief while they were joined by Manahara Manatunga (aerospace engineer) who did the preliminary aerodynamics analysis. Manahara also did a control system simulation which shows the CHAR flying inside a “moving control box” inside the airway.

In October 2016, Akshayan Rajasingam (physics major with an MSc specialized in simulation development) joined the team to work on the airways and ARTMS. Mevan Pathberiya (aeronautical engineer) joined soon after, and took over Arjuna’s work on the hovering demonstrator since he had decided to move overseas after 3 years. Mevan is now building the Mark 3 version which will hover and fly on the wing. Late last year, Kavindi De Silva (3 years in astronomy) joined the team and is designing the airports per ICAO regulations. With this technically strong team in place, Tilak works closely with the CAASL on regulatory issues, and with potential clients and investors on the business side.

The established viability of using drones for transport

Currently, there are operations that use drones to deliver goods. DHL pioneered commercial delivery with a 1 kg package to an island 12 km off the German coast almost 3 years ago. The more recent example is Zipline which delivers 150+ blood packs per day to 21 hospitals in Rwanda. Dubai just announced that they will have a one-person air taxi service by July this year.

Getting certified is a lengthy process, especially for one where you are building an entire ecosystem for robotic air cargo transport. The concept demonstration and certification process–once they get funded–will take approximately 3-4 years. “Most people think we are just building a small quadcopter and constantly want to know why we are not done yet!” says Tilak with a smile.

Even though in the initial stages, that hasn’t stopped Tilak from pitching to people and finding potential clients who seem to want new things transported by air such as cash for ATMs, live crabs, etc. ExpoLanka has stated that they plan on becoming the first robotic cargo airline. Grasshoppers by Kapruka and Quickee have expressed their desire to use the RACN to revolutionize their businesses. Having found the first set of potential clients, it becomes a lot easier to seek funding since they are still being bootstrapped using Tilak’s pension.

Many of us when asked, “If you had one wish, what would it be?” would give the answer “to end world hunger.” Tilak and his small team in Havelock Town are getting set to do that. This is the story of Tilak Dissanayake and his team, going to fly where no one has flown before: a world without hunger.

Its so impressive, i would like to know if i can get the email of this inventors.

Well, you can reach out to Tilak Dissanayake on Facebook. He’s generally active.