Microsoft plans to launch smart band in the UK

With wearables and smart watches being the “in” thing these days, Microsoft decided to join the fray as well. Their device, called the Microsoft Band, was on sale in the US for a while and they also plan to launch it in UK in the coming month. It attempts to challenge the Apple Watch whilst being cheaper yet doing many of the same things.

The device is really meant for those who are into fitness and training. It measures your steps, calories burned, and heart rate via a tap on the Band’s rectangular screen.

In addition to the fitness tracking, the Band also gives you the functionality of a smartwatch such as buzzing when you get emails and texts or an incoming call. One element that stands out is the software. The Health app is actually cross-platform and available for iOS and Android as well as Windows Phone. All in all, an impressive device which does quite a bit more than most of the simple fitness trackers on the market – and which competes with Apple’s Watch in terms of functionality.

Although the band may not win any awards in the looks category, it looks okay to me. But then again, apparently the setup guide tells you that you may choose to wear the device on the inside of your wrist. Is this a hint to hide the band if you’re too embarrassed to show it?

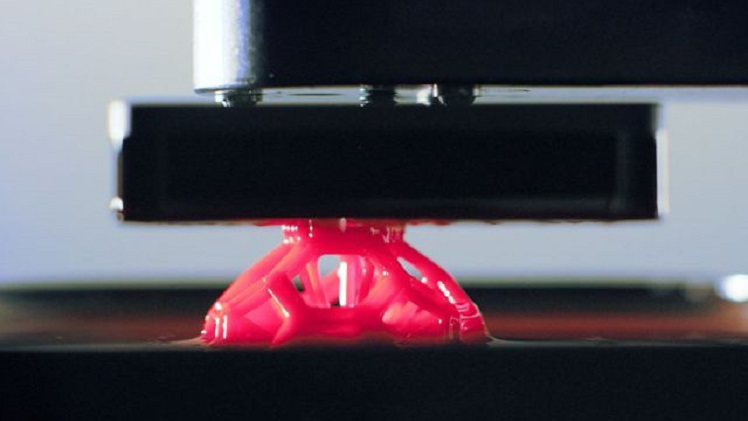

3D printer that uses light and oxygen to ‘grow’ solid objects

A 3D printing process that controls light and oxygen has been demonstrated at the Technology, Entertainment and Design (TED) conference in Vancouver.

Carbon3D, the company responsible for this stated that the revolutionary new process could make way to print objects such as car parts, medical devices and even shoes. It functions by applying different levels of light and oxygen to a pool of resin. The light is used to harden the resin, whilst oxygen stops hardening. By delicately controlling the levels of each, the resin can be forced into complex shapes.

The process draws inspiration from the movie Terminator 2, in which the T-1000 robot appears out of a pool of metallic liquid.

On the stage, the Carbon3D machine printed a plastic ball in 10 minutes. Whereas according to Carbon3D chief executive Prof Joseph DeSimone, it would usually take around 10 hours.

Traditional 3D printing has its flaws he says, referring to the time taken to print objects and that objects created by traditional 3D printing are often mechanically weak as they’re made up of multiple layers.

In comparison, his method is approximately 25 to 100 times faster and can print solid final parts, with the potential to actually be around 1,000 times faster.

Carbon3D hopes to have its product out commercially within a year and to develop the ability to print on materials other than resin.

Dyson invests in Sakti3 to create solid-state battery

Sakti3, a Michigan-based battery maker, is making use of solid-state technology to keep your devices running longer. Dyson, the vacuum cleaner company, is investing $15 million to Sakti3’s efforts to pull this off.

A normal lithium-ion battery uses a liquid electrolyte to produce a charge. Sakti3 aims to replace that liquid with solid lithium electrodes. The result would pack more power into a battery.

The trick is to move from the prototype stage to actual large-scale production. This is where Dyson comes in. They plan to help commercialize Sakti3’s battery, by including them in Dyson products first, then making them available to other device makers.

Solid-state batteries can deliver other benefits apart from more power and lower costs. They’re more environmentally friendly when compared to lithium-ion batteries, and by doing away with flammable liquid electrolyte, solid-state batteries can create a lesser chance for battery explosions.

GIPHY App Key not set. Please check settings